RO Feed Flush – Discussing

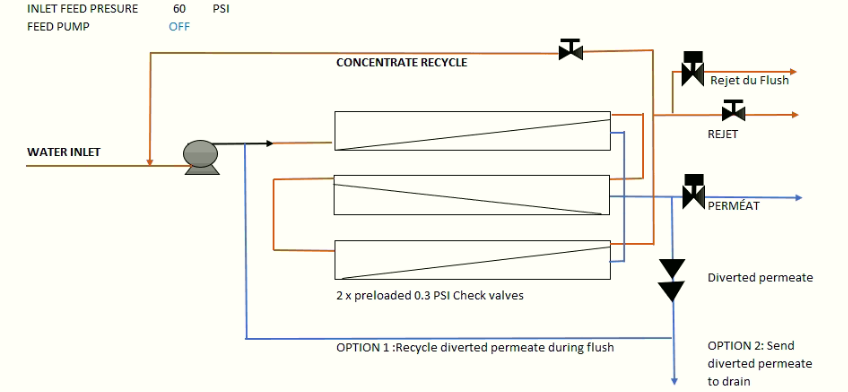

During flush, pump can be off. Feed water is around 60 psi, permeate divert solenoid valve is closed, but diverted permeate pressure that is around 30 psi (less than inlet pressure) cannot enter in feed flush because inlet water pressure is too high. So permeate in note recycled.

During production, when diverted permeate line is connected to pump outlet, there is a pressure of 150-180 psi that is applied to permeate divert line and also to the check valves that is on that line. These check valves are not designed to undergo to so high pressure. They will break.

The solution will be to send permeate to drain. But when permeate is connected to drain, during system normal operation (production) as the preloaded check on diverted permeate line is just 0.3 psi (too low), even with permeate divert solenoid valve is opened, part of permeate is sent to drain.

What will be needed for smooth operation is to connect diverted solenoid valve to drain and install 5-10 psi preloaded valve on the permeat diverted line

Mon Agora – Blog La parole est à moi

Mon Agora – Blog La parole est à moi